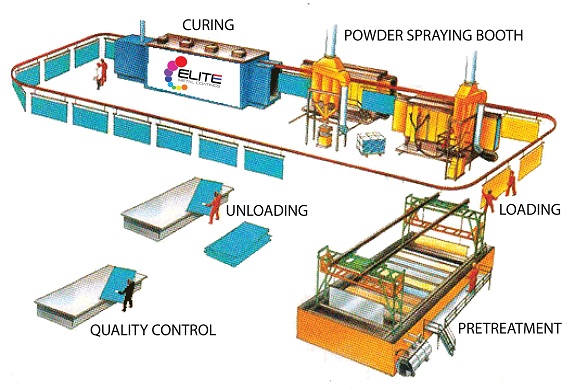

SOLID POWDER COATING LINE

The company currently has a debut production capacity of over 100 tons per month. The first step in the course of Powder-coating involves a Pre-treatment Process. Aluminium supplied direct from the extrusion process is often contaminated with oil and other residues, which will affect the longevity of the final coating.

It is vital therefore that the pre-treatment is correctly carried out to a very high standard. The process includes stages like Degreasing, Acid-Etching and Chromating. Rinsing with demineralized water in between the three stages is mandatory in order to Achieve the desired result, for this purpose we are also equipped with a fully equipped water de-ionizing system.

Benefits of Solid Powder Coating

-

Interior Use :

In the case of powder coating materials for interior use, we provide a range of epoxy polyester powders in varied shades. -

Solid Powder Coating :

Over-sprayed powder can be controlled and re-used giving a coating efficiency that can be in excess of 95%. -

Exterior Use :

we provide our customers with a range of powders in Pure Polyester. These powders are thermosetting powders based on durable polyester resins. -

Benefits :

Excellent resistance to solvents and other chemicals. Excellent aesthetics and adhesions. Exceptional interior stability. Tough, durable, long lasting coating for metals. Excellent U-V resistence and outdoor durability. Provides a good corrosion protection layer.